This was the last in the series of transformer winding controllers developed for Micro Tool and Machine. It was an amazing work of their craftsmen!

The main mandrel was driven by a large stepper motor, giving fine pitched accuracy on the winding. There was a second, smaller stepper motor driving a traverse that payed out the wire onto the mandrel, moving left to right on a lead screw.

The mandrel and traverse stepper motors made characteristic sounds as they indexed, accelerated and decelerated, giving the machine a unique personality.

There was a tap forming head above the mandrel which moved with the traverse head, through which the wire passed. At a given point, the mandrel would stop, clamps would come down onto the wire on either side of the tap former, a clamp wrapped the wire in the middle, then twisted 2 complete turns as it pulled up – while the clamps on either side, operated with pneumatics, would slide in. This formed a perfect wire tap, where a long bolt could be passed through to the top of the transformer.

The placement of the wire tap was critical, otherwise the tap bolt would not line up with the insulator and hole in the casing. I took very careful measurements of all aspects of the machine, then worked the math so that I could determine exactly how far ahead to stop the mandrel to make the tap, and then have it wind down to the correct spot. As the rotation speed of the mandrel was well known (and set by the controller using a stepper motor), a payout encoder on the wire at the tap former gave constant information for the circumference of the winding. From this, and knowing the geometry of the machine, the exact point that the mandrel had to decelerate and stop, could be calculated. The amazing thing was – it worked!

The last cool feature of this machine was duct tap insertion – a compartment of insulating rods was kept on the side, and could be pneumatically pushed up into one-way catch slots on the ends of the winding mandrel. This provided spacing between layers, or between windings.

All of this made for a fantastic sight. Almost autonomous transformer winding! Although the operator was still required to baby-sit the machine, in case anything went wrong. Of course, they had to change wires for LV and HV (LV wire was more like a wide copper foil), weld to the ends (propane welding of copper!) and tie off things when appropriate.

I was so enthused about it, that I borrowed Lorne’s camera and made a video of it in operation. I’ll have to dig up that tape, digitize it and post it sometime!

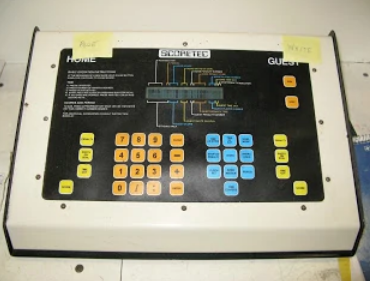

The machine had multiple processors on multiple boards, coordinating all this activity. The traverse controller was implemented with a Motorola MC68701, programmed by Lorne and by me; the tap forming controller was implemented with a Motorola MC68705U5, programmed by Mike Stasenski, and I did the programming on the MC6800 on the main controller, coordinating all their activities. I designed the “piggyback board” which contained the very-cool PCL-240K stepper motor controller for the mandrel, the “traverse board” and the “connector board” where all the different boards wired to for the interchange of communications.

This machine went to Delta Transformers in St. Jean-sur-Richelieu, Quebec. In 1988, I visited the plant and saw my machine in action. The engineer responsible for the machine, Guy Desormeaux, told me that the company had recently been acquired, and that this transformer winding machine was fiercely sought after!